• One tool for cutting, spreading and squeezing • 5117 models also suitable for pulling • Suitable for a variety of operations, from rapid intervention in vehicle rescue to USAR • You can gain access to a modern vehicle with just one tool* • Suitable for under water use • Your choice: CT 5111 for highest spreading force, CT 5117 for highest spreading distance tested on a 2014 model Opel Insignia, avoiding the pillars

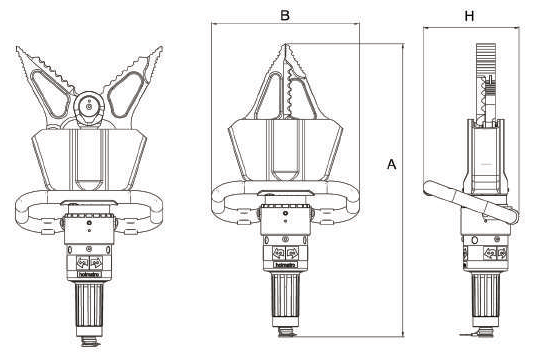

Holmatro combi tools CT 5111 (RH) & CT 5117 (RH):

Ultra-lightweight with high performance

Lower weight, smallersize, high performance

Holmatro now introduces a new generation of ultra-lightweight,compact combi tools for rapid

intervention in vehicle rescue and the extrication of persons trapped in emergency situations.Combining cutting and spreading capability these multifunctional hydraulic rescue tools can be used for a variety of applications.Thanks to their low weight and compact dimensions they are easy to carry, handle, transport and store and extremely suitable for use in confi ned spaces.

Depending on the nature of your operation you can choose between different models: hand-, pump or battery-operated and fitted with short arms or long arms. The short armed 5111 models are your best choice if you need a higher spreading force and the long armed 5117 models if a higher spreading distance is more important. Simply pick the most suitable tool for your job and you’re ready to go!

Extremely compact & ultra-lightweight

• Easy to carry, handle, transport and store

• Ideal for use in confined spaces

Connectable to all Holmatro pumps

• The separate pump decreases the weight of the tool and increases maneuverability

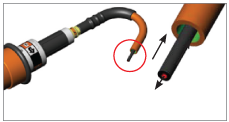

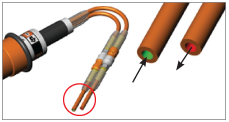

• CORE Technology makes setup quick and easy: only one hose to connect to pump and tool

Optimal performance to weight ratio

• Extremely high spreading force compared to size and weight (5111 models)

• Extremely high spreading distance compared to size and weight (5117 models)

• High cutting force compared to size and weight (both models)

Equipped with i-Bolt

• Flat central bolt construction for better access to narrowspaces

• Squeezes the blades together directly, which results in less blade separation and a better cutting performance

Carrying handle with integrated LED lighting

• Provides illumination when rescue scene lighting is (still absent)

• Never work in your own shadow by day

Also available with 360° rotatable,flat foldable carrying handle (RH models)

• Continuous swivel with 11 locking positions for use of the tool at almost any angle

• Collapsible for extra compact transportation and storage

| What is CORE™ Technology? | ||||||

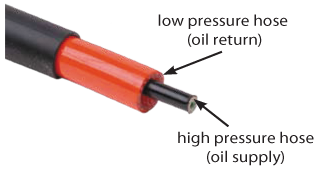

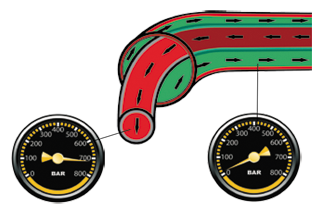

| CORE™ Technology (Coaxial Rescue Equipment Technology) refers to the hoses, couplers (and valves) of a rescue system. In other words the way hydraulic oil is directed from the pump to the tool and vice versa. A traditional dual hose system consists of a separate pressure and return hose connecting pump and rescue tool. A CORE™ system consists of only one hose: a high pressure inner hose inside a low pressure outer hose. The hydraulic principle and tool performance of CORE™ Technology and traditional technology are of course identical. |

|

|||||

| Why CORE™ Technology? | ||||||

| CORE™ Technology is a revolutionary turning point in rescue tool technology and definitely more than a new piece of equipment. It allows you, as a rescuer, to rethink and simplify your extrication techniques and your standard operating procedures. Once working with CORE™, you will discover the unprecedented benefits it offers. Compared to working with a traditional system, working with CORE™ is safer, easier & quicker. |

|

|

||||

| Safer | ||||||

| One hose system (hose in hose) - protected power | ||||||

| increased safety for the rescuer; high pressure hose inside and protected by low pressure outer hose | ||||||

|

|

|

||||

| CORE™ Technology is safer, more user-friendly, saves time and manpower | ||||||

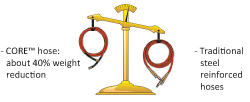

| Para-aramid fiber reinforced hose (no steel) | Safety couplers | |||||

| - no risk of kinking or pinholes | - one step auto-lock coupler - two step uncoupling system | |||||

|

|

|

|

|||

| CORE™ para-aramid reinforced | Dual steel reinforced | - couples and locks in just one push | - accidental uncoupling impossible during operation | |||

| Hose testing | According to international safety norms | |||||

|

- all testing according to every appropriate safety norm |

|

- 4:1 safety ratio for both pressure and return line - according to EN 13204 and NFPA 1936 (Certificates by independent body available) |

|

|||

| Easier & Quicker | |||||||||||||

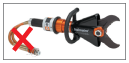

| Simple set up | Simple set up Changing tools under flow during use | ||||||||||||

| - connect CORE™ hose to pump or tool with or without pump running | - change tools any time without operating a release valve on the pump | ||||||||||||

|

|

|

|

saves precious manpower |

|||||||||

| Para-aramid reinforced hose | |||||||||||||

| - no kinking | - easy to handle / manoeuvre | ||||||||||||

|

|

|

|

||||||||||

| - easy to roll and unroll | - light weight | ||||||||||||

|

|

|

|||||||||||

| - easy storage | Maintenance friendly | ||||||||||||

|

- less couplers - less hoses - no pigtail hoses on tools - no release valves on pumps |

||||||||||||

| - all hoses with standard hose binders for easy storage | |||||||||||||

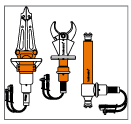

| Unique CORE™ couplers | Coupler mounted directly on the tools | ||||||||||||

| - 360° rotating couplers on tool and on pump; no hose entanglement | - no pigtail hoses necessary | - tool couplers not lying in the dirt |

- no swinging couplers - CORETM Technology |

||||||||||

|

|

|

|

|

|||||||||

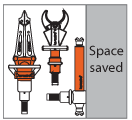

|

- compact, space saving in rescue vehicle | - Dual hoses | |||||||||||

|

|

|

|||||||||||

| - maintenance friendly flat face couplers | |||||||||||||

| One hand coupling | |||||||||||||

|

|

|

|

||||||||||

|

|||||||||||||

| - easy to clean | - no dirt inside couplers | ||||||||||||

|

|

||||||||

| Technical data Specifications | 5000 Series Combi Tools | ||||||||

| model | CT 5111 | CT 5111 RH | CT 5117 | CT 5117 RH | |||||

| article number | 150.012.307 | 150.012.308 | 150.012.310 | 150.012.311 | |||||

| equipped with (connector type) | CORE | CORE | CORE | CORE | |||||

| max. working pressure | bar/Mpa | 720 / 72 | 720 / 72 | 720 / 72 | 720 / 72 | ||||

| spreading distance | mm | 281 | 281 | 431 | 431 | ||||

| max. spreading force | kN/t | 457 / 46.6 | 457 / 46.6 | 54 / 5.5 | 54 / 5.5 | ||||

| min. spreading force (EN 13204) | kN/t | 48 / 4.9 | 48 / 4.9 | 28 / 2.9 | 28 / 2.9 | ||||

| max. cutting opening | mm | 196 | 196 | 352 | 352 | ||||

| max. cutting force | kN/t | 206 / 21 | 206 / 21 | 204 / 20.8 | 204 / 20.8 | ||||

| round bar (EN 13204) | mm | 24 | 24 | 24 | 24 | ||||

| max. squeezing force | kN/t | 44 / 4.5 | 44 / 4.5 | 27 / 2.8 | 27 / 2.8 | ||||

| pulling distance | mm | -- | -- | 426 | 426 | ||||

| max. pulling force | kN/t | -- | -- | 30 / 3.1 | 30 / 3.1 | ||||

| required oil content (effective) | cc | 55 | 55 | 55 | 55 | ||||

| weight, ready for use | kg | 8 | 7.9 | 8.6 | 8.6 | ||||

| dimensions (LxWxH) | mm | 545x275x192 | 545x217x115 | 641x275x192 | 641x217x115 | ||||

| temperature range | -20 °C + 55 °C | ||||||||

| EN 13204 | BK48/281-E-8.0 | BK48/281-E-7.9 | BK28/431-E-8.6 | BK28/431-E-8.6 | |||||

| Accessories | (only for model 5117) | ||||||||

| Item | CT 5117 | CT 5117 RH | |||||||

| 1 - Pulling attachments set | 150.182.241 | 150.182.241 | |||||||

| 2 - Pulling chains set | 150.582.548 | 150.582.548 | |||||||