Advanced “Hybrid” Nozzle Technology – Ambassador Monitor Trailers feature a unique “hybrid” nozzle that functions as an automatic or fixed flow nozzle. During automatic operation, the nozzle will respond to varying water supply of 2,000 to 6,000 GPM (7,570 to 22,700 LPM), to maintain a nearly constant tip pressure of approximately 100 PSI (6.9 bar), thus maximizing its effective reach distance. This is particularly useful in applications where the water supply may be inadequate or variable, or to establish initial discharge while more supply lines are being connected.

In fixed flow mode, the nozzle can be preset with the included fixed position plugs (flow stops) to a desired flow rate between 2,000 and 6,000 GPM (7,570 and 22,700 LPM), based on the specific situation. Flow rate and reach distance increase as the water supply increases with a nearly constant K-factor. If the flow is not hitting the target and you need to boost the distance, simply increase the water supply (increase pump engine throttle). Once the flow rate reaches the set point, it performs as a conventional fixed flow nozzle. There is no need to shut down operations to adjust flow unless you need more beyond the set point. This mode is desirable for foam proportioning operations on storage tank fires or other hazards requiring specific application densities.

Hydro-Foam Proportioning – The Ambassador nozzle is capable of Hydro-Foam proportioning at flow rates up to 6000 GPM at 1% or 3% and at 3000 GPM at 6% using remote jet pump technology for easy and efficient foam application. Jet pumps are supplied with the trailer. A “flood-plate” disperses the rich water/foam solution (from the jet pumps) around the inner periphery of the master stream for thorough mixing.

Hydro-Chem™ Capability – The Ambassador nozzle is capable of delivering up to 100 lb (45 Kg)/s of dry chemicals with its dry chemical accessory kit for 3-dimensional or pressure fires. To use the Hydro-Chem™ capability, feed the foam solution to the trailer unit via the water inlet connections from other foam systems such as Williams WATP and/or Hot Shot foam systems. The Hydro-Foam flood plate can be easily removed by hand and replaced with a chemical extension tube. This tube can be fitted with your choice of dry chemical choke tips that allow the dry chemical flow rate at 25, 50, 75, or 100 lb/s.

The Hydro-Chem™ option allows the dry chemical, such as WILLIAMS FIRE & HAZARD CONTROL PKW, to be propelled inside the protective “tunnel” of the master stream. This enables the dry chemical to reach a greater distance than is possible with conventional equipment. Dry chemical manifolds are available for interconnecting WF&HC Gorilla 500 LB PKW units or common wheeled dry chemical units to produce the required flow.

Highly Efficient Waterway - The trailer has a large integrated stainless steel waterway and inlet manifold with standard Storz couplings. Various combinations of inlet sizes are available for maximum connectivity. The monitor waterway has 8” (200 mm) full-flow construction to provide minimum friction loss and maximum efficiency. The nozzle features a hard coat anodized aluminium and stainless steel assembly. Constructed of stainless steel, the monitor is designed to provide years of reliable service.

User-friendly Operations – The nozzle provides easy pattern control, ranging from full fog for personnel protection to straight stream for maximum reach and delivery (via a full wrap-around handle attached to the outer sleeve.) The monitor allows a full monitor articulation of 360˚ rotation, and down to -10˚ and up to +80˚ vertical travel for the tiller bar models. The trailer features an approximately 400 gallon (1,500 L) ballast for stability to counteract the reactionary force generated by the large flow. The ballast is below an anti-skid grip deck for firm footing, even when the surface is completely wet. Flowing up to 6,000 GPM, a firefighter operating the device using the standard tiller-bar will experience the freedom of smooth, rapid horizontal and vertical movement. For enhanced safety and ease of use, an electric/hydraulic version is also available, which can be remotely controlled from up to 300 ft (91 m) away and with gear operation as backup. The remote-controlled unit is fully self-contained and requires no additional power supply.

For the European market, a version built and certified to European Road Legal standards is available.

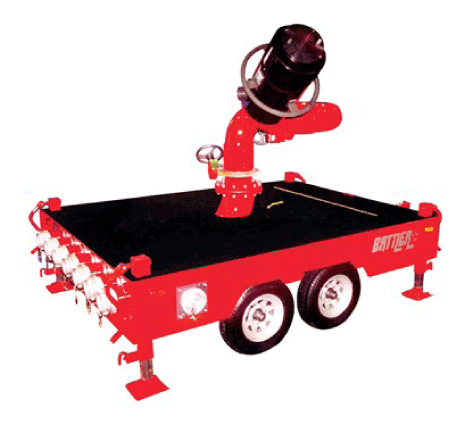

Advanced “Hybrid” Nozzle Technology – The integrated nozzle on the Battler Monitor Trailer has the capability to perform as an automatic pressure or fixed flow nozzle. During automatic operation, the nozzle will respond to varying flows to maintain a nearly constant tip pressure of 100 PSI (6.9 bar) ± 10%, maximizing the reach distance for a given discharge flow. This allows the monitor to be extremely useful for applications where the water supply may be inadequate, variable, or to establish initial discharge while more supply lines are being connected.

In fixed flow mode, the nozzle can be pre-set with the included fixed position plugs (flow stops) to a desired flow rate between 4,000 and 10,000 GPM (15,100 and 37,800 LPM) for specific situations. As the water supply increases, flow rate and reach distance increase with a nearly constant K-factor. If the flow is not hitting the target and you need to boost distance, simply increase the water supply (by increasing pump engine throttle if water is supplied by a pump). Once the flow rate hits the set point, it performs as a conventional fixed flow nozzle with a variable K-factor. This mode is important for foam proportioning operations on storage tank fires or other hazards requiring specific application densities, thus a specific flow rate.

Hydro-Foam Proportioning – The Battler nozzle is designed with Hydro-Foam proportioning at flow rates up to 10,000 GPM (37,800 LPM) @1% or 8,000 GPM (30,000 LPM) @ 3%, using remote jet pump technology for easy and efficient foam application. Jet pumps are supplied with the trailer. A “flood-plate” disperses the rich water/foam solution (from the jet pumps) around the inner periphery of the master stream for thorough mixing.

Highly Efficient Waterway - The trailer has a 12” (300 mm) integrated stainless steel waterway to provide minimum friction loss, maximum efficiency, and years of reliable service. The inlet manifold features standard Storz couplings with caps. Various combinations of inlet sizes are available to provide maximum connectivity. The monitor is built with a 10” (250 mm) waterway. The nozzle features a hard coat anodized aluminium and stainless steel assembly.

User-friendly Operations – The nozzle has a full wrap-around handle attached to the outer sleeve to provide an easy pattern control from full fog for personnel protection to straight stream for maximum reach and delivery. The monitor allows a full articulation of 360˚ rotation and down to +15˚ and up to +75˚ vertical travel. The trailer features a 400 gallon (1,500 L) ballast for stability to counteract the reactionary force generated by the large flow. The ballast is below an anti-skid grip deck for firm footing even when the surface is completely wet. The dual gear operated monitor can be easily and safely controlled by a firefighter for pan and tilt. Four point trailer jacks ensure stability during operation.

Each Batter Monitor Trailer is supplied as a tandem axle bumper pull trailer with a tool box and a foam proportioning package included. Following options are also available: