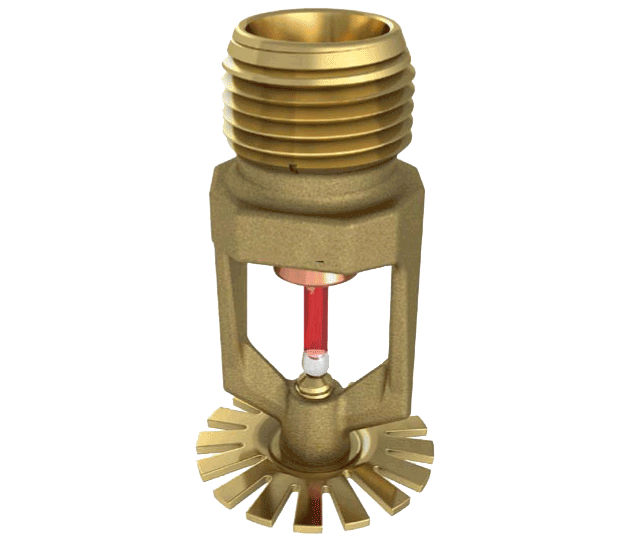

Water is the most widely used and most readily available fire-extinguishing agent. It is a very effective agent for controlling and extinguishing combustion. As an extinguishing agent, it is safe, nontoxic, relatively noncorrosive, and stable. Water principally extinguishes solid fuel fires by cooling the fuel surface. It also extinguish fire by smothering action through the dilution of air supply around the fuel sources. Water is applied to fires by both portable equipment and fixed systems such as sprinkler systems, standpipe systems and private fire service mains systems.