Holmatro’s 5000 series spreaders are designed with the rescuer in mind: lighter than ever, without concessions on performance. They are available for CORE systems with pump and hose or in Greenline battery-driven versions.

| What is CORE™ Technology? | ||||||

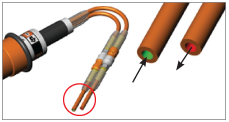

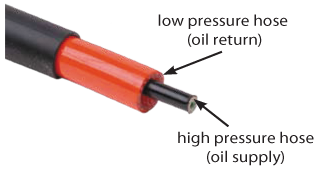

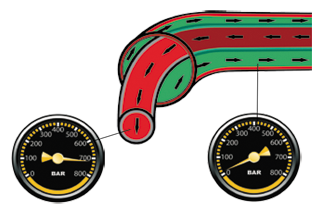

| CORE™ Technology (Coaxial Rescue Equipment Technology) refers to the hoses, couplers (and valves) of a rescue system. In other words the way hydraulic oil is directed from the pump to the tool and vice versa. A traditional dual hose system consists of a separate pressure and return hose connecting pump and rescue tool. A CORE™ system consists of only one hose: a high pressure inner hose inside a low pressure outer hose. The hydraulic principle and tool performance of CORE™ Technology and traditional technology are of course identical. |

|

|||||

| Why CORE™ Technology? | ||||||

| CORE™ Technology is a revolutionary turning point in rescue tool technology and definitely more than a new piece of equipment. It allows you, as a rescuer, to rethink and simplify your extrication techniques and your standard operating procedures. Once working with CORE™, you will discover the unprecedented benefits it offers. Compared to working with a traditional system, working with CORE™ is safer, easier & quicker. |

|

|

||||

| Safer | ||||||

| One hose system (hose in hose) - protected power | ||||||

| increased safety for the rescuer; high pressure hose inside and protected by low pressure outer hose | ||||||

|

|

|

||||

| CORE™ Technology is safer, more user-friendly, saves time and manpower | ||||||

| Para-aramid fiber reinforced hose (no steel) | Safety couplers | |||||

| - no risk of kinking or pinholes | - one step auto-lock coupler - two step uncoupling system | |||||

|

|

|

|

|||

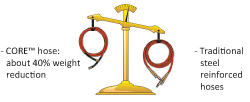

| CORE™ para-aramid reinforced | Dual steel reinforced | - couples and locks in just one push | - accidental uncoupling impossible during operation | |||

| Hose testing | According to international safety norms | |||||

|

- all testing according to every appropriate safety norm |

|

- 4:1 safety ratio for both pressure and return line - according to EN 13204 and NFPA 1936 (Certificates by independent body available) |

|

|||

| Easier & Quicker | |||||||||||||

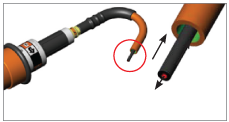

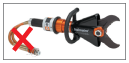

| Simple set up | Simple set up Changing tools under flow during use | ||||||||||||

| - connect CORE™ hose to pump or tool with or without pump running | - change tools any time without operating a release valve on the pump | ||||||||||||

|

|

|

|

saves precious manpower |

|||||||||

| Para-aramid reinforced hose | |||||||||||||

| - no kinking | - easy to handle / manoeuvre | ||||||||||||

|

|

|

|

||||||||||

| - easy to roll and unroll | - light weight | ||||||||||||

|

|

|

|||||||||||

| - easy storage | Maintenance friendly | ||||||||||||

|

- less couplers - less hoses - no pigtail hoses on tools - no release valves on pumps |

||||||||||||

| - all hoses with standard hose binders for easy storage | |||||||||||||

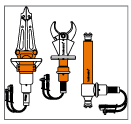

| Unique CORE™ couplers | Coupler mounted directly on the tools | ||||||||||||

| - 360° rotating couplers on tool and on pump; no hose entanglement | - no pigtail hoses necessary | - tool couplers not lying in the dirt |

- no swinging couplers - CORETM Technology |

||||||||||

|

|

|

|

|

|||||||||

|

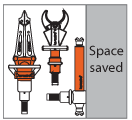

- compact, space saving in rescue vehicle | - Dual hoses | |||||||||||

|

|

|

|||||||||||

| - maintenance friendly flat face couplers | |||||||||||||

| One hand coupling | |||||||||||||

|

|

|

|

||||||||||

|

|||||||||||||

| - easy to clean | - no dirt inside couplers | ||||||||||||

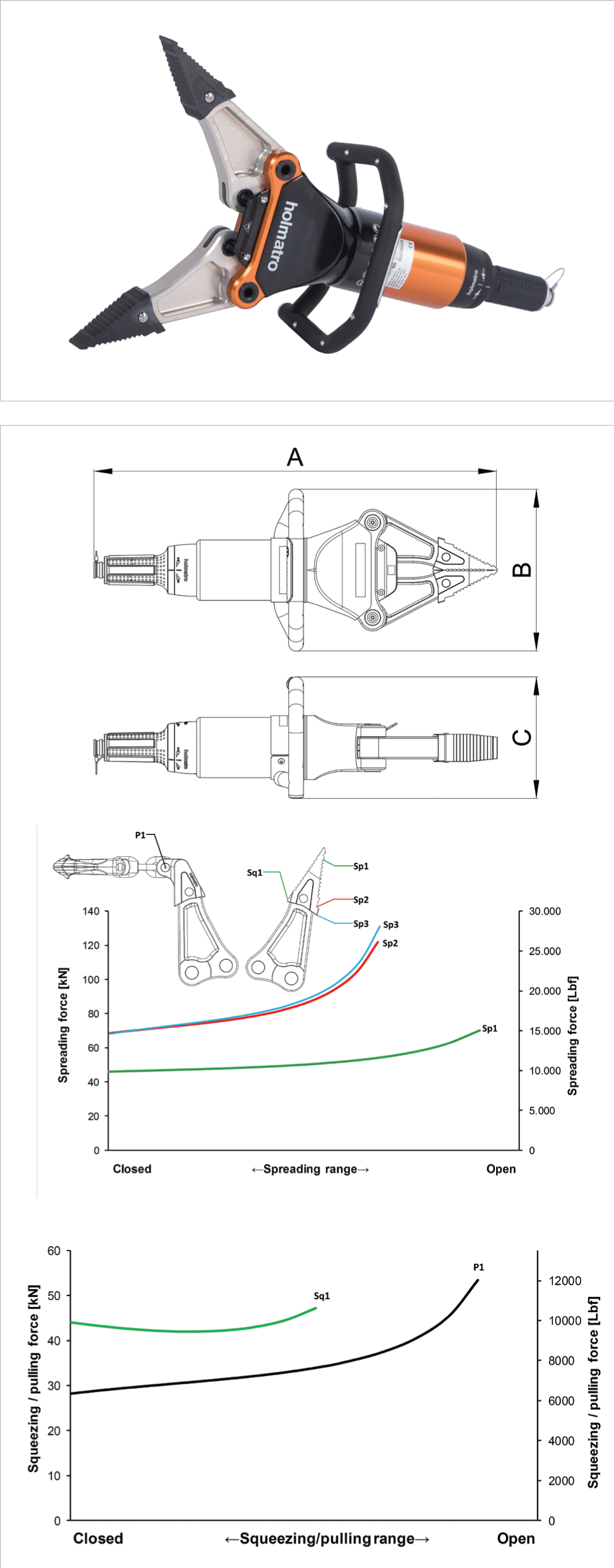

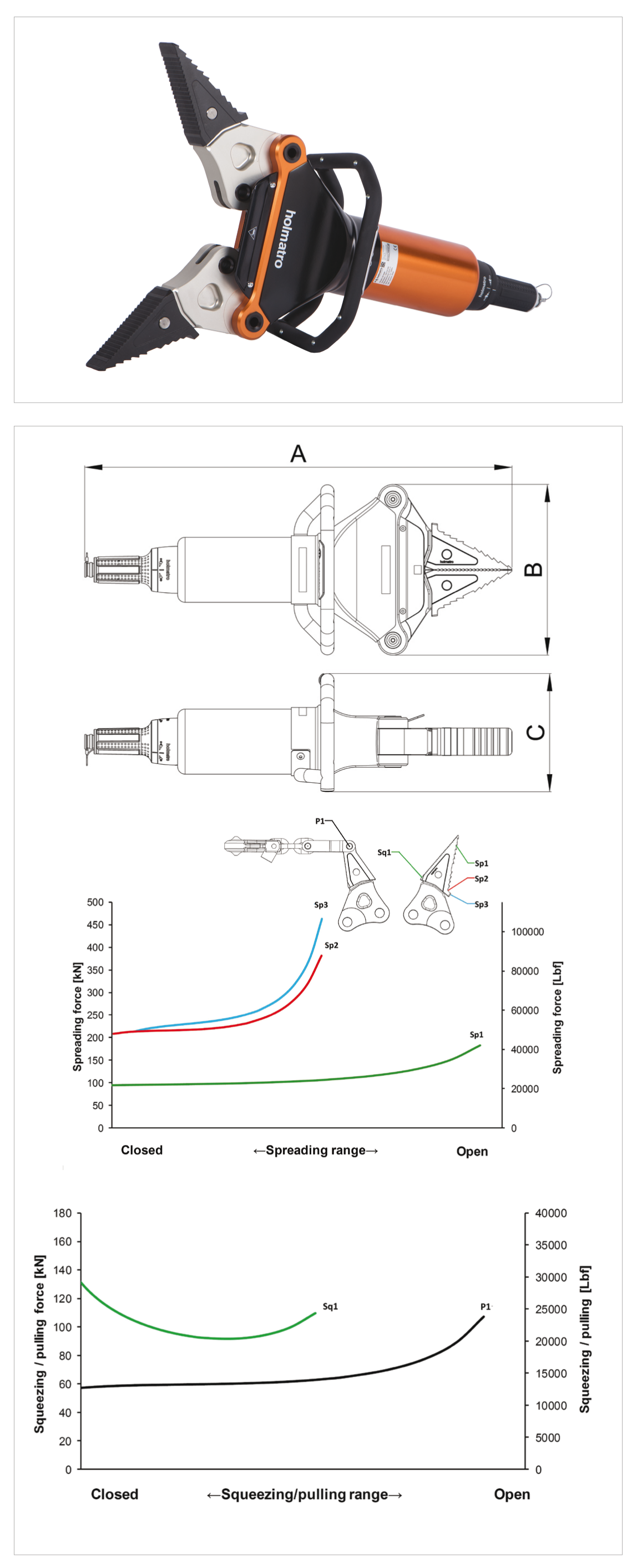

| Spreader | SP 5240 | |||

| article number | 150.012.324 |

|

|

| model | SP 5240 | ||

| equipped with (connector type) | CORE | ||

| short description | Spreader | ||

| max. working pressure | bar/Mpa | 720 / 72 | |

| spreading distance | mm | 725 | |

| pulling distance | mm | 610 | |

| max. spreading force | kN/t | 280 / 28.6 | |

| theoretical calculated spreading force | kN/t | 850 / 86.7 | |

| min. spreading force (EN 13204) | kN/t | 41 / 4.2 | |

| max. spreading force, 25mm/1in from the tip | kN/t | 93 / 9.5 | |

| max. squeezing force | kN/t | 59 / 6 | |

| max. pulling force | kN/t | 47 / 4.8 | |

| required oil content (effective) | cc | 226.4 | |

| hydraulic oil type | ISO-L HV VG 15/22 | ||

| weight, ready for use | kg | 14.5 | |

| temperature range | °C | 35 | |

| dimensions (AxBxC) | mm | 815 x 286 x 217 | |

| EN 13204 classification | AS41/725-14.5 | ||

| NFPA 1936, HPF | kN/t | 47 / 4.8 | |

| NFPA 1936, HSF | kN/t | 70 / 7.1 | |

| NFPA 1936, LPF | kN/t | 25 / 2.5 | |

| NFPA 1936, LSF | kN/t | 38 / 3.9 | |

| NFPA 1936 compliant | Yes | ||

| Safety factors / tests | |

| hydraulic safety factor | 2:01 |

| endurance test tool | 1000 cycles of opening and closing while arms are loaded |

| endurance test dead man’s handle | 6000 cycles |

| Accessories | |

| Cutting Tips, Set | 150.006.474 |

| Spreading Tips, Set | 150.006.475 |

| Pulling Attachments, Set | 150.182.274 |

| Accessories Set in Case | 150.182.288 |

| Pulling Chains Set | 150.582.152 |

| Pulling Chains, Set in Case | 150.582.021 |

| Spreader | SP 5240 CL | |||

| article number | 150.012.323 |

|

|

| model | SP 5240 CL | ||

| equipped with (connector type) | CORE | ||

| short description | Spreader | ||

| max. working pressure | bar/Mpa | 720 / 72 | |

| spreading distance | mm | 510 | |

| pulling distance | mm | 393 | |

| max. spreading force | kN/t | 131 / 13.4 | |

| theoretical calculated spreading force | kN/t | 850 / 86.7 | |

| min. spreading force (EN 13204) | kN/t | 40 / 4.1 | |

| max. spreading force, 25mm/1in from the tip | kN/t | 70 / 7.1 | |

| max. squeezing force | kN/t | 47 / 4.8 | |

| max. pulling force | kN/t | 47 / 4.8 | |

| required oil content (effective) | cc | 124 | |

| hydraulic oil type | ISO-L HV VG 15/22 | ||

| weight, ready for use | kg | 9.6 | |

| temperature range | °C | 35 | |

| dimensions (AxBxC) | mm | 685 x 274 x 207 | |

| EN 13204 classification | 47 / 4.8 | ||

| NFPA 1936, HPF | kN/t | 53 / 5.4 | |

| NFPA 1936, HSF | kN/t | 24 / 2.4 | |

| NFPA 1936, LPF | kN/t | 35 / 3.6 | |

| NFPA 1936, LSF | kN/t | Yes | |

| NFPA 1936 compliant | 150.012.323 | ||

| Safety factors / tests | |

| hydraulic safety factor | 2:01 |

| endurance test tool | 1000 cycles of opening and closing while arms are loaded |

| endurance test dead man’s handle | 6000 cycles |

| Accessories | |

| Spreading Tips, Set | 150.006.473 |

| Pulling Attachments, Set | 150.182.273 |

| Accessories, Set in Case | 150.182.289 |

| Pulling Chains Set | 150.582.152 |

| Pulling Chains, Set in Case | 150.582.021 |

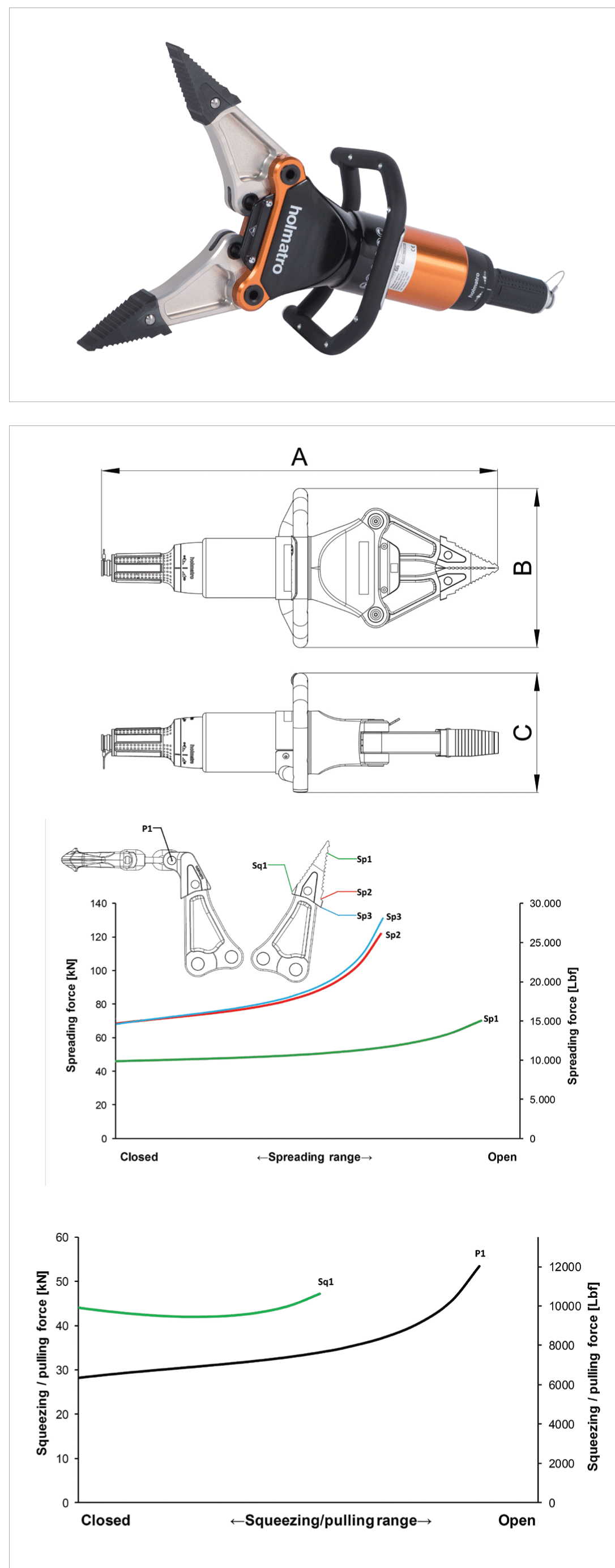

| Spreader | SP 5250 | ||||

| article number | 150.012.324 |

|

||

| model | SP 5250 | |||

| equipped with (connector type) | CORE | |||

| short description | Spreader | |||

| max. working pressure | bar/Mpa | 720 / 72 | ||

| spreading distance | mm | 725 | ||

| pulling distance | mm | 610 | ||

| max. spreading force | kN/t | 366 / 37.3 | ||

| theoretical calculated spreading force | kN/t | 670 / 68.3 | ||

| min. spreading force (EN 13204) | kN/t | 51 / 5.2 | ||

| max. spreading force, 25mm/1in from the tip | kN/t | 127 / 13 | ||

| max. squeezing force | kN/t | 135 / 13.8 | ||

| max. pulling force | kN/t | 67 / 6.8 | ||

| required oil content (effective) | cc | 291 | ||

| hydraulic oil type | ISO-L HV VG 15/22 | |||

| weight, ready for use | kg | 15.9 | ||

| temperature range | °C | 35 | ||

| dimensions (AxBxC) | mm | 826 x 285 x 215 | ||

| EN 13204 classification | AS51/725-15.9 | |||

| NFPA 1936, HPF | kN/t | 67 / 6.8 | ||

| NFPA 1936, HSF | kN/t | 97 / 9.9 | ||

| NFPA 1936, LPF | kN/t | 31 / 3.2 | ||

| NFPA 1936, LSF | kN/t | 46 / 4.7 | ||

| NFPA 1936 compliant | Yes | |||

| Safety factors / tests | ||||

| hydraulic safety factor | 2:1 | |||

| endurance test tool | 1000 cycles of opening and closing while arms are loaded | |||

| endurance test dead man’s handle | 6000 cycles | |||

| Accessories | |

| Cutting Tips, Set | 150.006.474 |

| Spreading Tips, Set | 150.006.475 |

| Pulling Attachments, Set | 150.182.274 |

| Accessories Set in Case | 150.182.288 |

| Pulling Chains Set | 150.582.152 |

| Pulling Chains, Set in Case | 150.582.021 |

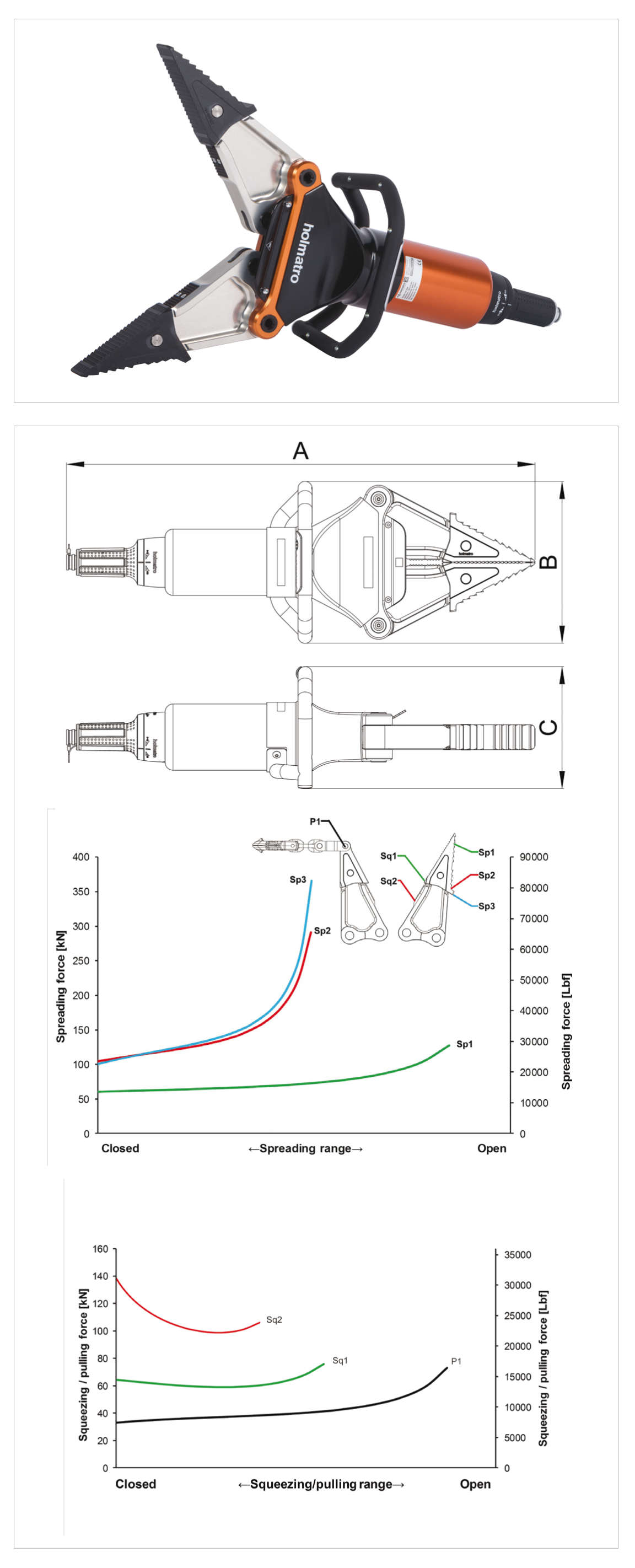

| Spreader | SP 5260 | |||

| article number | 150.012.325 |

|

|

| model | SP 5260 | ||

| equipped with (connector type) | CORE | ||

| short description | Spreader | ||

| max. working pressure | bar/Mpa | 720 / 72 | |

| spreading distance | mm | 822 | |

| pulling distance | mm | 701 | |

| max. spreading force | kN/t | 522 / 53.2 | |

| theoretical calculated spreading force | kN/t | 650 / 66.3 | |

| min. spreading force (EN 13204) | kN/t | 62 / 6.3 | |

| max. spreading force, 25mm/1in from the tip | kN/t | 148 / 15.1 | |

| max. squeezing force | kN/t | 127 / 13 | |

| max. pulling force | kN/t | 82 / 8.4 | |

| required oil content (effective) | cc | 384 | |

| hydraulic oil type | ISO-L HV VG 15/22 | ||

| weight, ready for use | kg | 19.6 | |

| temperature range | °C | 35 | |

| dimensions (AxBxC) | mm | 900 x 322 x 223 | |

| EN 13204 classification | BS62/822-19.6 | ||

| NFPA 1936, HPF | kN/t | 82 / 8.4 | |

| NFPA 1936, HSF | kN/t | 117 / 11.9 | |

| NFPA 1936, LPF | kN/t | 37 / 3.8 | |

| NFPA 1936, LSF | kN/t | 58 / 5.9 | |

| NFPA 1936 compliant | Yes | ||

| Safety factors / tests | |

| hydraulic safety factor | 2:1 |

| endurance test tool | 1000 cycles of opening and closing while arms are loaded |

| endurance test dead man’s handle | 6000 cycles |

| Accessories | |

| Cutting Tips, Set | 150.006.466 |

| Spreading Tips, Set | 150.006.472 |

| Pulling Attachments, Set | 150.182.275 |

| Accessories, Set in Case | 150.182.290 |

| Pulling Chains | 150.582.261 |

| Pulling Chains, Set in Case | 150.582.020 |

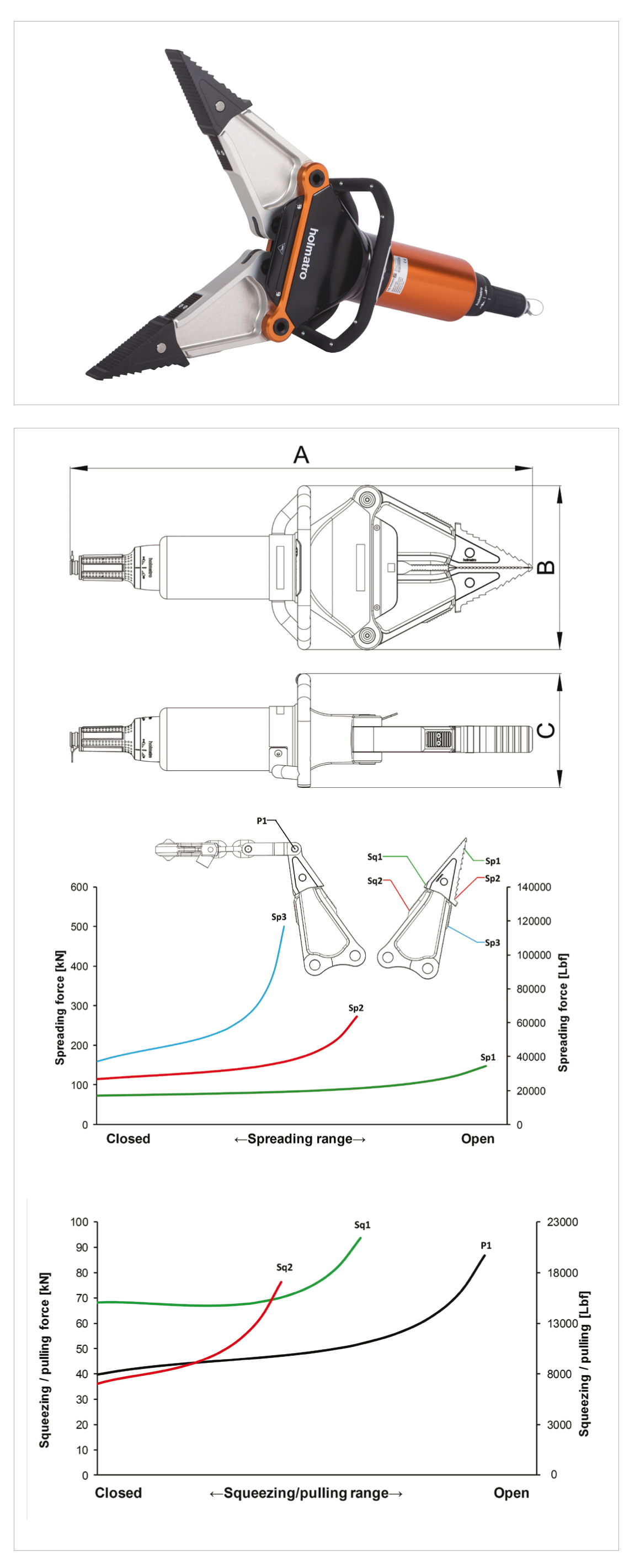

| Spreader | SP 5280 | ||||

| article number | 150.012.326 |

|

||

| model | SP 5280 | |||

| equipped with (connector type) | CORE | |||

| short description | Spreader | |||

| max. working pressure | bar/Mpa | 720 / 72 | ||

| spreading distance | mm | 662 | ||

| pulling distance | mm | 538 | ||

| max. spreading force | kN/t | 463 / 47.2 | ||

| min. spreading force (EN 13204) | kN/t | 83 / 8.5 | ||

| max. spreading force, 25mm/1in from the tip | kN/t | 183 / 18.7 | ||

| max. squeezing force | kN/t | 159 / 16.2 | ||

| max. pulling force | kN/t | 99 / 10.1 | ||

| required oil content (effective) | cc | 384 | ||

| hydraulic oil type | ISO-L HV VG 15/22 | |||

| weight, ready for use | kg | 19.4 | ||

| temperature range | °C | 35 | ||

| dimensions (AxBxC) | mm | 801 x 322 x 220 | ||

| EN 13204 classification | CS83/662-19.4 | |||

| NFPA 1936, HPF | kN/t | 99 / 10.1 | ||

| NFPA 1936, HSF | kN/t | 142 / 14.5 | ||

| NFPA 1936, LPF | kN/t | 53 / 5.4 | ||

| NFPA 1936, LSF | kN/t | 74 / 7.5 | ||

| NFPA 1936 compliant | Yes | |||

| Safety factors / tests | ||||

| hydraulic safety factor | 2:1 | |||

| endurance test tool | 1000 cycles of opening and closing while arms are loaded | |||

| endurance test dead man’s handle | 6000 cycles | |||

| Accessories | |

| Cutting Tips, Set | 150.006.466 |

| Spreading Tips, Set | 150.006.472 |

| Pulling Attachments, Set | 150.182.275 |

| Accessories, Set in Case | 150.182.290 |

| Pulling Chains | 150.582.261 |

| Pulling Chains, Set in Case | 150.582.020 |