The JUMBO MF-200 mobile foam unit designed for effective fire fighting in high risk areas, such as petrol stations and storage plants, paints or solvent stores, boiler and engine rooms, and industrial processes involving combustible liquids The BAVARIA MF-200 WHEELED foam unit designed for effective fire fighting in high risk areas, such as petrol stations and storage plants, paints or solvent stores, boiler and engine rooms, and industrial processes involving combustible liquids

|

Technical Specifications:

|

|||

|

Chassis

|

|||

|

Material

|

Steel

|

||

|

Handle

|

Equipped with suitable handle for easy movement by one person

|

||

|

Rollers

|

Equipped with two rear rollers and front steering roller for easy maneuvering

|

||

|

Hoses carriers

|

Equipped with rear delivery hose carries and two side foam branch holders

|

||

|

|

|||

|

Container

|

|||

|

Material

|

Fiber glass suitable for all types of foam concentrates

|

||

|

Capacity

|

200 l

|

||

|

Top Filler Opening

|

Screw-type cap

|

||

|

Bottom Plug Opening

|

Equipped

|

||

|

Pick up Hose Opening

|

Equipped

|

||

|

|

|||

|

Hoses

|

|||

|

Material

|

Flat nylon hose with internal rubber lining

|

.jpg) |

|

|

Quantity

|

2 hoses, one for connection with an external pressurized water source & the others for foam delivery

|

||

|

Hose Diameter & Length

|

64 mm (2 ½ inch) , 30 m length

|

||

|

Bursting Pressure

|

Over 48 bar

|

||

|

Hose Coupling

|

Equipped with Morris 63 mm (2 ½ inch) coupling

|

||

| Foam Proportioning System | ||

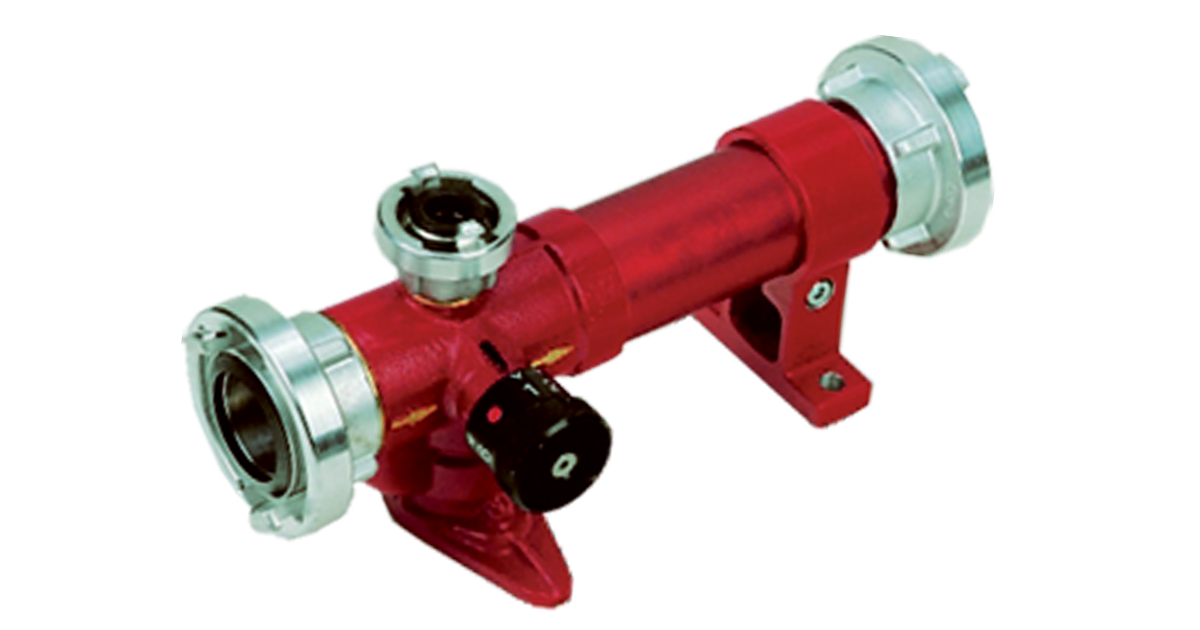

| A) In-line Inductor | ||

| Manufacturer | AWG – Germany |

|

| Mixing ratio | 1 – 6 % | |

| Maximum Flow Rate | 400 l/min | |

| B) Low/Medium Expansion (heavy/medium foam) Air-aspirating Foam Nozzle | ||

| Design | Air aspirating stainless steel foam nozzle with an expansion rate of 15:1 on low setting and 60:1 on medium setting. It can be adjusted via a select lever, providing added flexibility depending on the hazard |

|

| Country of Origin | Germany | |

| Type | M4/S4 | |

| Material | Stainless steel | |

| Flow Rate | 400 l/min at 5 bar | |

| Coupling Type | 2.5 inch instantaneous coupling BS 336 | |

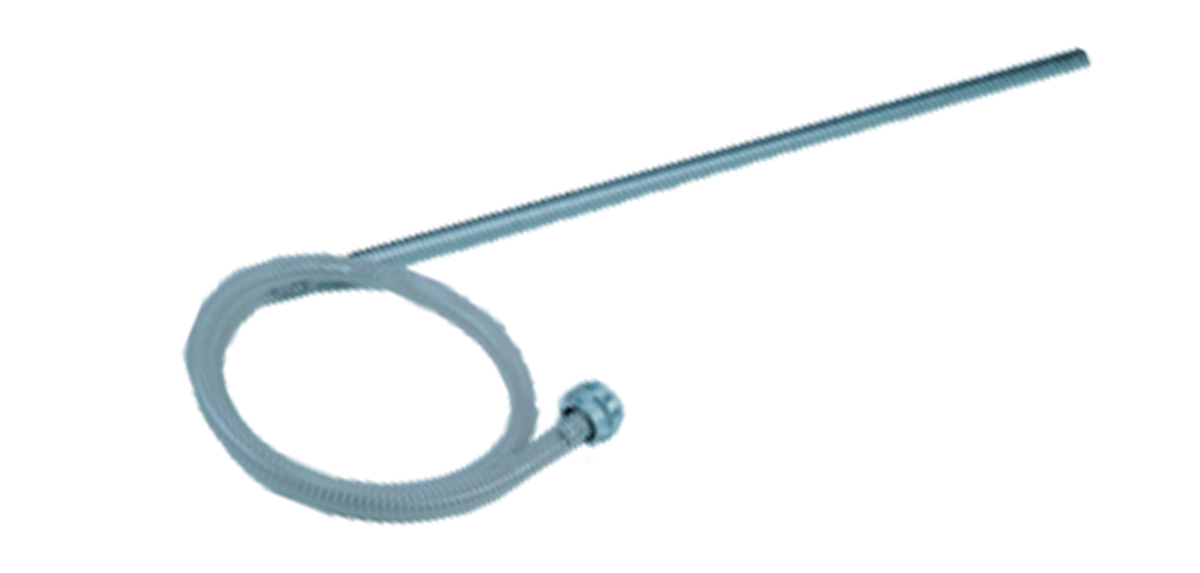

| c) Pick up Hose | ||

| Country of Origin | Germany |

|

| Length & Diameter | 1.5 m length, 19 mm internal diameter | |

| Storz Coupling | Provided on one side of the hose | |

| Warranty: | |

| Period of Warranty | 1 Year |

| Coverage of the Warranty | Against material failure and production defects |

| Method of Warranty Coverage | Limited to the replacement of the defected part or product after verification that the failure is covered by the scope of the warranty |

| Warranty Exclusions | Failures due to misuse, mishandling, or inspection or repair by an unauthorized dealer or entity |

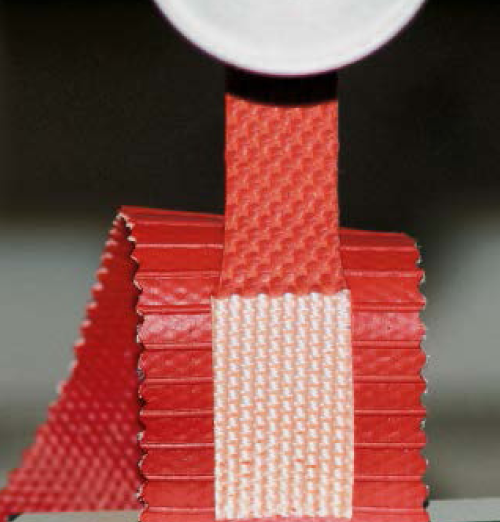

| Option: DELIVERY HOSE - Inside and Outside Rubber lined Fire Fighting Hose, Type 3 | |||

| Origin Country | Germany |

|

|

| Fabrication | Inside and Outside Rubber lined Fire Fighting Hose, Type 3 | ||

| Construction |

Inside: very smooth for minimum friction loss Jacket of 100 % high tenacity synthetic polyester yarn, circular woven, embedded in a rubber compound provides optimum protection of the jacket High-quality Nitrile/PVC compound is forced through the jacket Outside: longitudinal ribs for excellent abrasion resistance |

||

| Hose Coupling | Equipped with (2 ½ inch) instantaneous coupling BS 336. | ||

| Hose Diameter | Inch | 64 mm (2½ inch) |

|

| Bursting Pressure | bar | 50 (DIN) | |

| Working Pressure (1:3 Safety) | bar | 17 (DIN) | |

| Working Pressure (1:4 Safety) | bar | 12 | |

| Weight (+/– 5 %) | g/m | 495 | |

| Wall Thickness (+/– 0,2 mm) | mm | 2,3 | |

| Theoretical Tensile Strength thin kg 1.700 | 5.1 | ||

| Approvals/Certificates |

DIN 14811:2008-01+A2:2014-08 BS 6391:2009 Type 3 M.E.D. 96/98/EC |

||