The BAVARIA 1100-WF Fire Fighting Trailer is a water/foam rapid intervention double -axle trailer with mounted portable fire fighting pump, designed for effective fire fighting in high risk areas such as industrial and petroleum complexes, oil terminals and military locations.

| Chassis | ||||

| Manufactured of | Steel channel sections | |||

| Axles | Double axles of 2.1 ton capacity for each axle | |||

| Draw Bar | Provided with a towing attachment and towing eye | |||

| Hand Brake | Provided, attached to the draw bar | |||

| Drop-leg | Provided at rear | |||

| Down Screw Wheel | Vertically adjustable with handbrake – attached to the draw bar | |||

| Rear Lights | Equipped | |||

| Wiring | Provided with cable and plug for connection with the electric system of the towing vehicle | |||

| Mudguards and Rear Bumper | Equipped | |||

| Allowed Speed | Up-to 80 km/h on asphalt roads | |||

| Braking System | Equipped | |||

|

Extra Advantage |

Spare tire | Equipped | ||

| Rear Locker | Equipped with a rear locker for stowage of two delivery hoses and accessories | |||

| Pump Base | Provided with a sliding base-plate for easier access and unloading of the pump for independent use in narrower sites | |||

| Surface Treatment | Under carriage is treated against rust by ELBO system | |||

| Stainless Steel Water/Foam Tank | ||||

| Design and Capacity |

Consists of two compartments: 1000 l capacity water compartment, 100 l capacity foam compartment |

|||

| Filling Ratio | 90 % for both compartments | |||

| Construction | Constructed of high quality welded 3 mm stainless steel sheets | |||

| Baffles | Each compartment is provided with 3 mm stainless steel baffle | |||

| Drain Vent | Provided for each compartment | |||

| Level Indicator | Equipped for each compartment | |||

|

Water Compartment |

Manhole | Equipped | ||

|

Ventilation Opening |

Equipped | |||

| Filling Pipe | Equipped with a 2 ½ inch, instantaneous coupling BS336 inlet and a ball valve | |||

|

Foam Compartment |

Filling Opening | Equipped | ||

|

Delivery Opening |

Equipped with an opening connected to the foam proportioning system through a pick-up hose | |||

| Fixation | Fixed by bolts and rubber seats to the chassis | |||

| ZIEGLER - Portable Fire Pump | ||

| Type | Ultra Power 4 |

|

| Country of Origin | GERMANY | |

| PUMP OUTPUT |

|

|

|

PUMP |

|

|

| PRIMING SYSTEM | Proven fully automatic TROKOMAT PLUS | |

| GAUGES AND CONTROLS |

|

|

|

ENGINE |

|

|

| LIGHTING | 1 Halogen spotlight, extendible and can be swiveled and tilted in all directions | |

|

CARRYING FRAME |

High-strength light metal frame with four ergonomically hinged and turntable handles as well as rubberized cold hand guard. | |

| DIMENSIONS |

|

|

| WEIGHT | approx. 188 ready for action | |

| Foam Proportioning System | ||

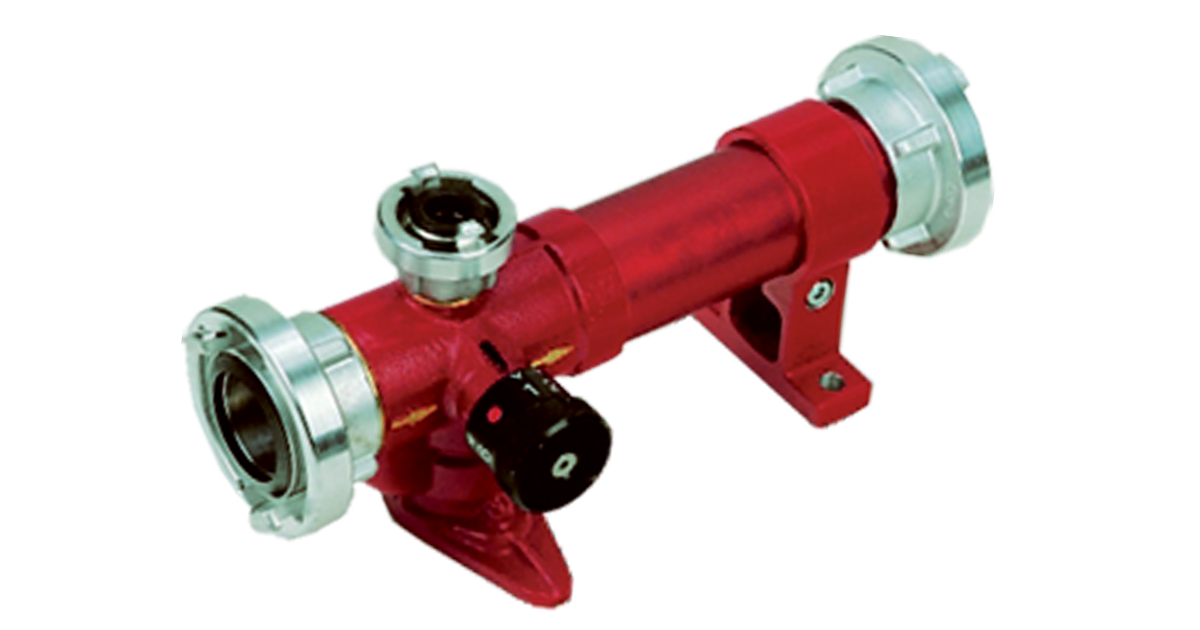

| A) In-line Inductor | ||

| Manufacturer | AWG – Germany |

|

| Mixing ratio | 1 – 6 % | |

| Maximum Flow Rate | 400 l/min | |

| B) Low/Medium Expansion (heavy/medium foam) Air-aspirating Foam Nozzle | ||

| Design | Air aspirating stainless steel foam nozzle with an expansion rate of 15:1 on low setting and 60:1 on medium setting. It can be adjusted via a select lever, providing added flexibility depending on the hazard |

|

| Country of Origin | Germany | |

| Type | M4/S4 | |

| Material | Stainless steel | |

| Flow Rate | 400 l/min at 5 bar | |

| Coupling Type | 2.5 inch instantaneous coupling BS 336 | |

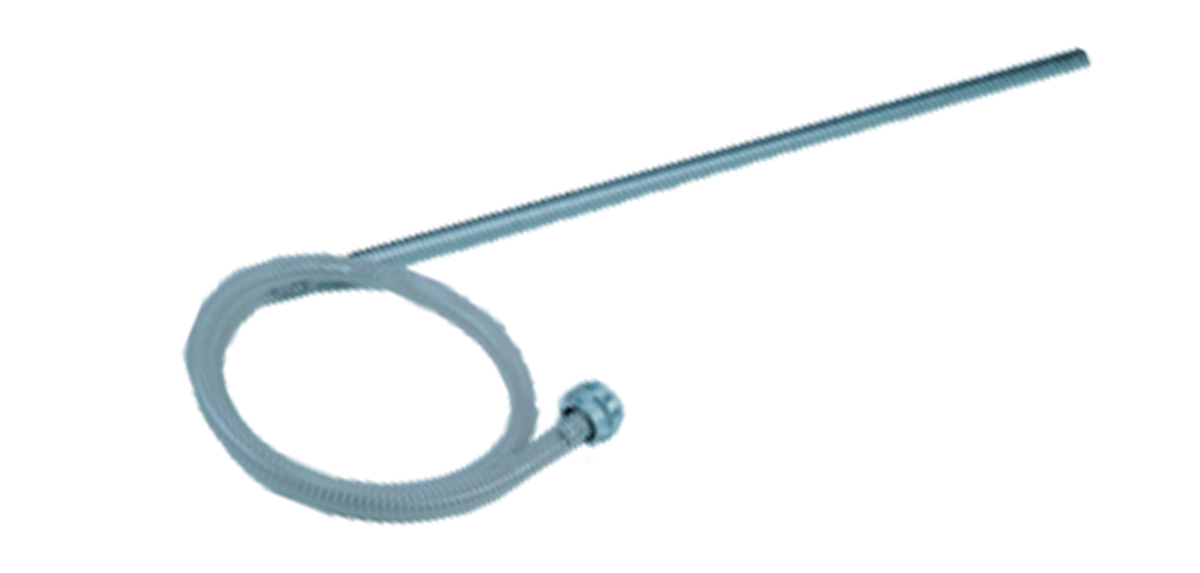

| c) Pick up Hose | ||

| Country of Origin | Germany |

|

| Length & Diameter | 1.5 m length, 19 mm internal diameter | |

| Storz Coupling | Provided on one side of the hose | |

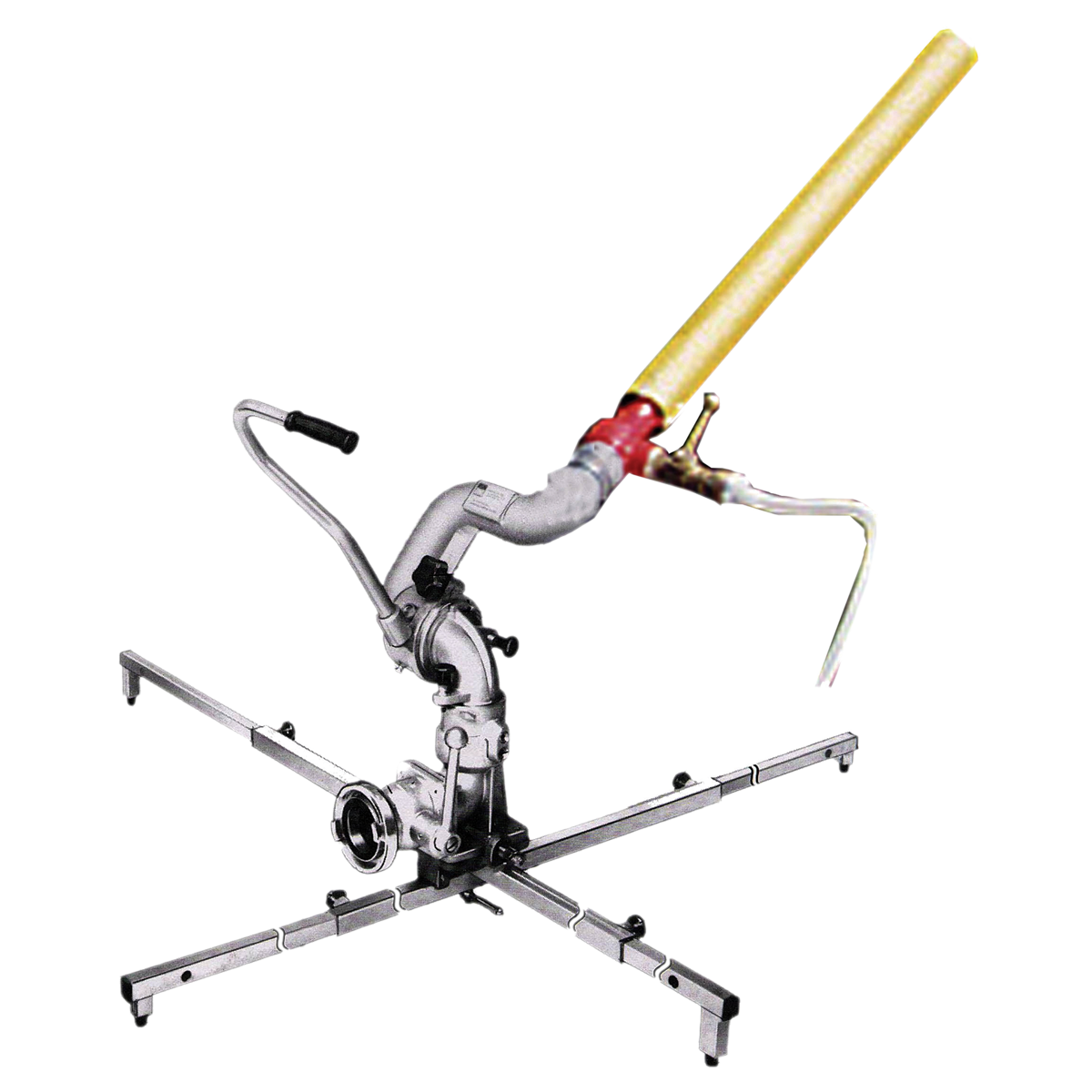

| 4 - WATER/FOAM MONITOR TYPE AWG HH 1260 | |||

| Model | HH 1260 |

|

|

| Manufacturer | AWG, Germany | ||

| Usage | Manual, easy to use on deck and can also be erected on its ground base and used separately | ||

| Operation | Controllable flow & Shoulder prop | ||

| Output | Water / Foam |

Generated foam up to 15000 l/min at 7bar (according to foam concentrate specifications) |

|

| Water | 1200 l/min. (at 8 bar) | ||

| Throw Range | Water / Foam | 40 m at 10 bar | |

| Water | 52 m at 8 bar | ||

| Rotation | 360° | ||

| Vertical Movement | +25° to 90° | ||

| Air-aspirating Foam Nozzle | Self Priming with built-in inductor | ||

| Water Jet Nozzle | 26 mm | ||

| Extra Advantage | Provided with ground base for separate use in narrow sites | ||

| Option (Multi Purpose Water Tip) | For Jet, Spray and Fog upon request at extra cost | ||

| 5 - DELIVERY HOSES | ||

| Quantity | 4 |

|

| Type | Bavaria Standard, Type 1 | |

| Hose Diameter and Length | 64mm (2 ½ inch) x 30 m | |

| Fabrication | Flat nylon hose with internal rubber lining | |

| Optimum Working Pressure Range | 17 bar | |

| Hose Bursting Pressure | Over 48 bar | |

| Hose Coupling |

Equipped with instantaneous coupling BS 366 64 mm (2 ½ inch) |

|

| WATER JET BRANCHPIPE | ||

| Quantity | 2 |

|

| Material | High strength aluminium alloy | |

| Operation Mode | Full jet | |

| Optimum Working Pressure Range | 5-8 bar | |

| Max. Output | 215 l/min when the ball valve is completely opened | |

| Max. Throw Range | 29 m | |

| Coupling Type | 2.5 inch instantaneouscoupling BS 336 | |

| Gasoline Engine Generator for Lighting and Rescue Operations | |

| Quantity | 1 |

| AC Output Voltage | 400 V / 230 V |

| Maximum AC Output | At least 6 KVA |

| High Intensity Working light | |

| Type | Halogen high intensity light |

| Quantity | 1 |

| Line Voltage | AC 220/240 V |

| Lamp Power | 500 W at least |

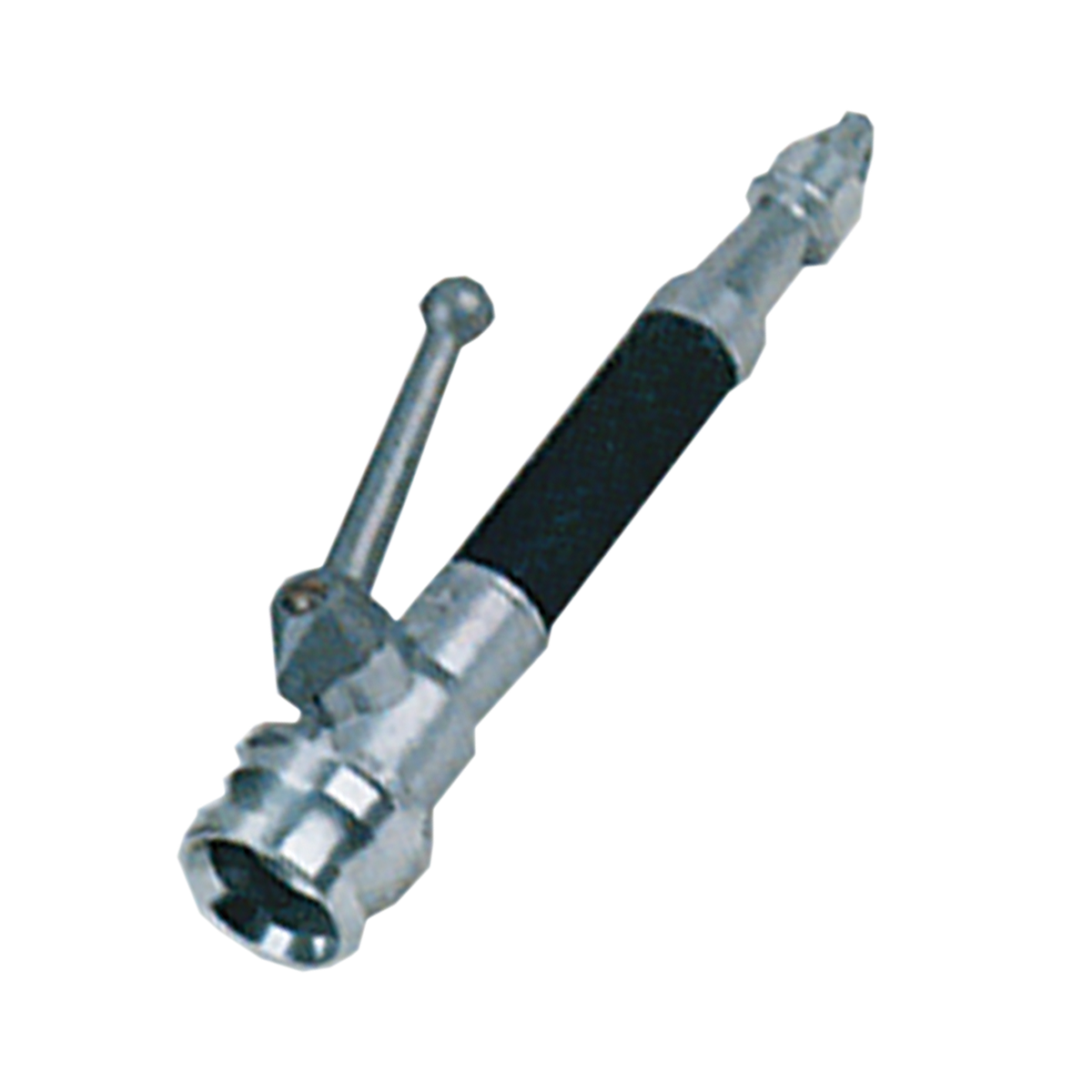

| Option at Extra Cost: Multipurpose BAVARIA TYPHOON 400 | ||||

| Model | TYPHOON-400 |

|

||

| Country of Origin | Germany | |||

| Operation Modes | Full jet, spray and water curtain | |||

| Extra Advantage | Variable flow | |||

| Inlet Fitting | 64 mm (2 ½ inch) instantaneous coupling BS 336 | |||

| Nominal Water Inlet Working Pressure (bar) | 6 | |||

| Variable Flow Rate | Full Jet | 130 (l/min), 235 (l/min) and 400 (l/min) |

|

|

| Spray Jet | ||||

| Effective Throw Distances @ 6 bar | Full Jet | 26 m, 42m and 40 m | ||

| Spray Jet | 11 m, 14 m and 16 m | |||

| Spray Angle | 0° to120° | |||

| Dimension (lxwxh) mm | 289x109x245 | |||

| Weight | 2.5 kg | |||

| Option at Extra Cost | Shoulder Prop. | |||

| Warranty: | |

| Period of Warranty | 1 Year |

| Coverage of the Warranty | Against material failure and production defects |

| Method of Warranty Coverage | Limited to the replacement of the defected part or product after verification that the failure is covered by the scope of the warranty |

| Warranty Exclusions | Failures due to misuse, mishandling, or inspection or repair by an unauthorized dealer or entity |

| 3 - TOHATSU Portable Pump, TYPE: VC82ASE | |||

| Model | VC82ASE |

|

|

| Engine | Type | 2-stroke,2-cylinder, water cooled gasoline engine | |

| Authorized Output | 55 PS (Horse power) | ||

| Fuel tank Capacity | Approx. 18 liters (4.76 US gals) | ||

| Starting System | Starter motor and automatic recoil system | ||

| Ignition | Flywheel magneto | ||

| Lubrication | Auto-mixing | ||

| Battery | 12 V-16Ah/5 h | ||

| Pump | Type | Single-suction, single-stage, high pressure turbine pump | |

| Discharge Outlet Coupling | Twin 64 mm (2 ½ inch) instantaneous coupling BS 366 | ||

| Suction inlet Coupling | 102 mm (4 inch) Storz coupling | ||

| Priming | Rotary-vane vacuum pump | ||

|

Pump Performance (suction height: 3 m) |

Over 2,050 l (Over 452 gals)/min, at 0.6 Mpa Over 1,800 l (Over 476 gals)/min, at 0.8 Mpa Over 1,500 l (Over 396 gals)/min, at 1.0 MPa |

||

| General | Overall Dimensions (lxhxw) | Approx. (742 x 760 x 682) mm – ( 29.2 x 29.9 x 26.8) inch | |

| Weight | 94 kg (207 lbs.) | ||

| Max. Suction Height | Approx. 9 m ( 29.5 feet) | ||

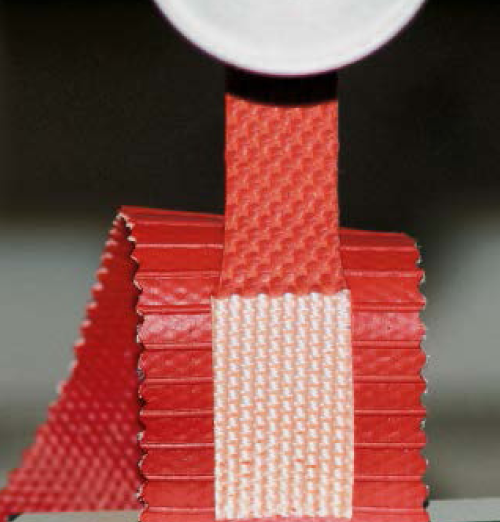

| Option: DELIVERY HOSE - Inside and Outside Rubber lined Fire Fighting Hose, Type 3 | |||

| Origin Country | Germany |

|

|

| Fabrication | Inside and Outside Rubber lined Fire Fighting Hose, Type 3 | ||

| Construction |

Inside: very smooth for minimum friction loss Jacket of 100 % high tenacity synthetic polyester yarn, circular woven, embedded in a rubber compound provides optimum protection of the jacket High-quality Nitrile/PVC compound is forced through the jacket Outside: longitudinal ribs for excellent abrasion resistance |

||

| Hose Coupling | Equipped with (2 ½ inch) instantaneous coupling BS 336. | ||

| Hose Diameter | Inch | 64 mm (2½ inch) |

|

| Bursting Pressure | bar | 50 (DIN) | |

| Working Pressure (1:3 Safety) | bar | 17 (DIN) | |

| Working Pressure (1:4 Safety) | bar | 12 | |

| Weight (+/– 5 %) | g/m | 495 | |

| Wall Thickness (+/– 0,2 mm) | mm | 2,3 | |

| Theoretical Tensile Strength thin kg 1.700 | 5.1 | ||

| Approvals/Certificates |

DIN 14811:2008-01+A2:2014-08 BS 6391:2009 Type 3 M.E.D. 96/98/EC |

||

| Period of Warranty | 1 Year |

| Coverage of the Warranty | Against material failure and production defects |

| Method of Warranty Coverage | Limited to the replacement of the defected part or product after verification that the failure is covered by the scope of the warranty |

| Warranty Exclusions | Failures due to misuse, mishandling, or inspection or repair by an unauthorized dealer or entity |