Inline Foam Eductors provide the simplest and most economical method of introducing a metered flow of foam concentrate into a pressurized water stream. As opposed to “Hydro-Foam™ Technology” which is used in union with master stream nozzles, these “Venturi-Type” foam proportioners are designed to be used in conjunction with a matched constant flow end-of-line device (e.g., nozzle), where adequate water pressure is available. The pressurized water stream creates a vacuum (the Venturi effect) which is used to suck foam concentrate into the eductor body. The dosing of the concentrate is controlled by either an orifice plate or a metering valve. The concentrate enters and mixes with the water stream. The foam solution exits through the outlet of the inductor.

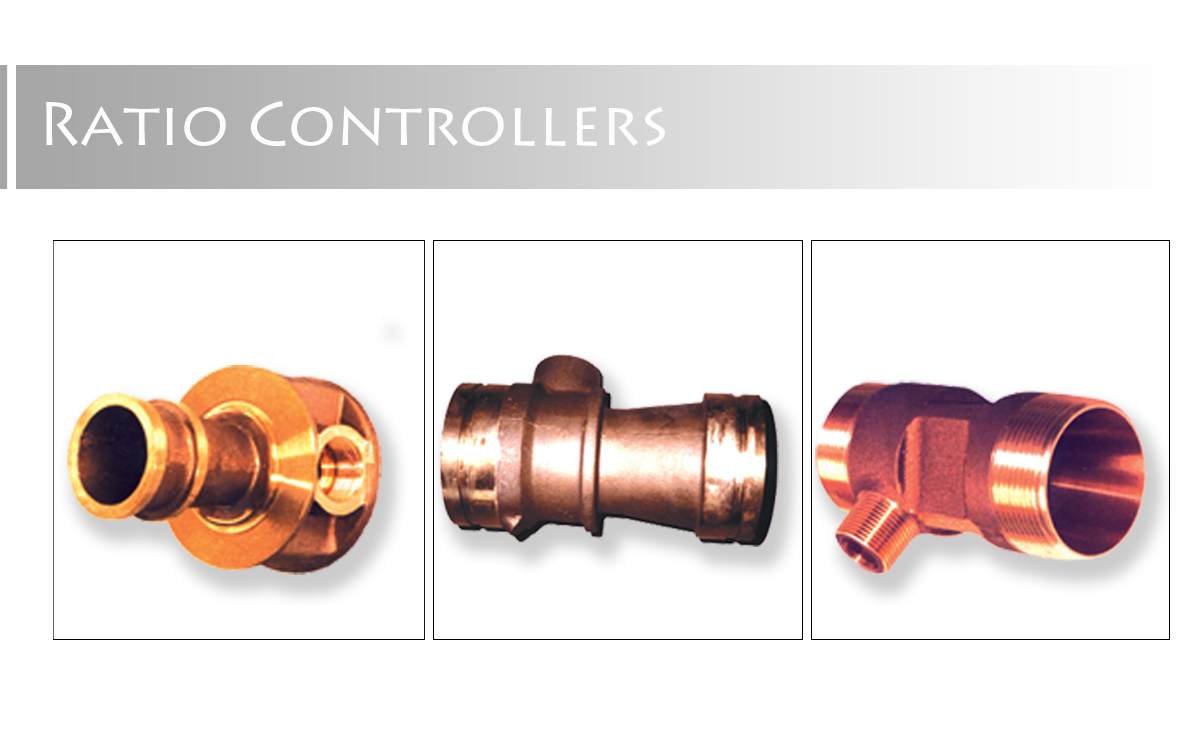

Ratio Controllers are modified venturi foam proportioners that accurately meter pressurized foam concentrate into the firefighting water stream. These foam proportioners are used in conjunction with balanced pressure systems, such as bladder tanks and pumped proportioning skids. In operation, firefighting water flows through the modified venturi, creating an area of lower pressure, which is referred to as the “metering pressure drop”. This metering pressure drop is directly affected by the firefighting water velocity as it flows through the venturi. The (1%, 3% or 6%) concentrate-to-water ratio is maintained over the entire flow range of each size ratio controller. However, each size ratio controller has a minimum flow rate/velocity requirement, and these minimums must be maintained for proper ratio controller operation. Available in three styles and various sizes, each Ratio Controller consists of the following components: body; metering orifice; inlet nozzle. These components are constructed of ASTM 85-5-5-5 bronze. The inlet nozzle is tapered and machined to a smooth finish to maximize water stream efficiency through the venturi. The foam concentrate metering orifice is sized to the exact type and percentage of foam concentrate to be used. Both the inlet nozzle and metering orifice are secured by a stainless steel retaining ring.

– 1 1/2 in. (F)NST water inlet for jet pump motive flow.

– 2 1/2 in. (M)NST rich foam solution outlet.

– 2 in. (M)NPSH foam concentrate inlet.

– 2 in. (F)NPSH foam concentrate hose.

– 2 in. (M)NPT PVC foam stinger.

– A version with a 2 in. cam-lock fitting for the hose and stinger is also available.